Vertical Logistics System

A Vertical Logistics System (VLS) is an automated storage and retrieval solution designed to maximize warehouse space by utilizing vertical height rather than horizontal floor area. By integrating advanced software with mechanical lifting technologies, these systems bring items directly to the operator (the “goods-to-person” principle). This eliminates unnecessary walking time, reduces the risk of manual handling injuries, and ensures high-density storage for businesses looking to scale their operations.

Leading Innovation in Vertical Logistics Automation

Established in 2015, Shanghai Ailift Automation System Co., Ltd. (Ailift) is a premier manufacturer specializing in the vertical conveying system niche. Deeply rooted in warehouse logistics and industrial automation, the company leverages technological innovation to provide a foundation for sustainable enterprise development. Guided by a “customer-centric” philosophy and a spirit of pioneering excellence, Ailift delivers highly efficient, customized cargo solutions and integrated “Vertical Conveying+” services designed to lead the industry’s intelligent transformation.

Customized Solutions

Production & Construction

Upgrades & Retrofits

Spare Parts Supply

Relocation

O&M Services

Ailift Automation's Partner

Product Specifications

Horizontal Pallet Transport Robot

Dense storage vertical conveying equipment is suitable for vertical handling scenarios in dense storage warehouses. The high-precision leveling design of the vertical conveyor meets the layer-changing requirements of shuttle cars, mother-daughter carts, and 4-directional vehicles, ensuring maximum utilization of storage space.

AGV Vertical Conveying

Suitable for AGV docking scenarios. AGVs can interface with conveyors at the entrance/exit of the vertical conveyor for loading/unloading, or can directly drive into the car of the vertical conveyor for layer changing. Patent technology ensures high-precision leveling of the car, making the AGV drive-in/drive-out process smooth and reliable.

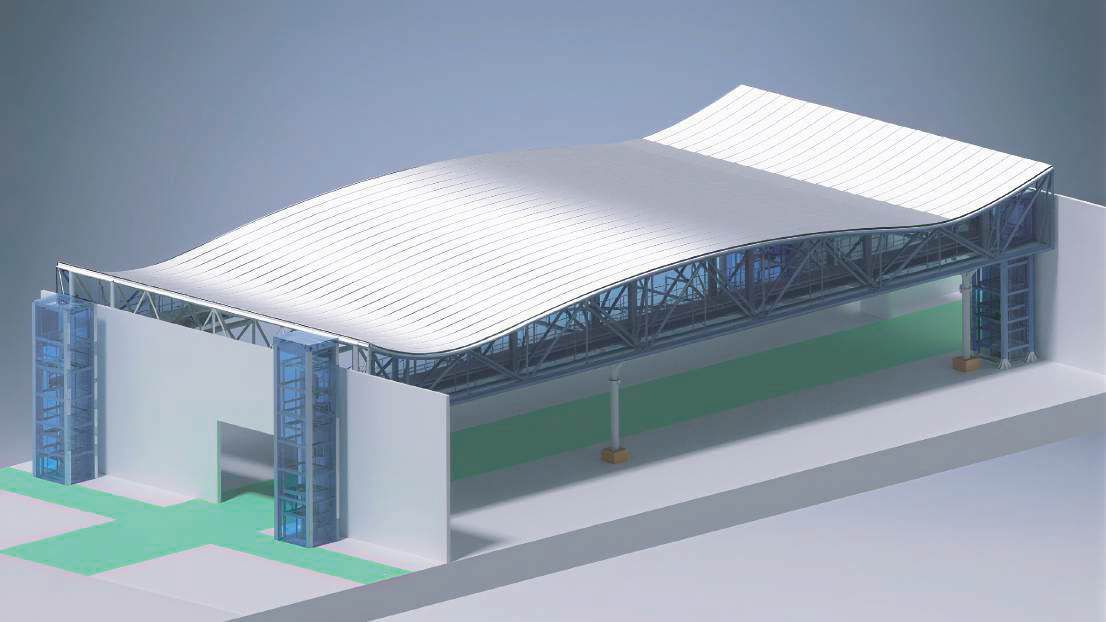

Outdoor Vertical Conveying

For special scenarios encountered in projects, we have developed cleanroom environment vertical conveying systems, cold storage vertical conveying systems, outdoor vertical conveying systems, explosion-proof vertical conveying systems, etc.

Depending on the specific working conditions and client requirements, weatherproof enclosures for outdoor applications are typically available in forms such as color steel plates or tempered glass.

The design process, based on thorough site surveys, fully considers factors including building settlement, earthquakes, typhoons, waterproofing, ventilation, and temperature to ensure a safe and reliable solution.

Connecting Gallery vertical Conveying System

The Connecting Gallery Vertical Conveying System is an intelligent logistics solution integrating lifting, conveying, control, and safety protection. It is particularly suitable for automated material transfer scenarios across campuses with high frequency and multiple varieties. It offers excellent industrial applicability and future upgrade potential in terms of efficiency, safety, flexibility, and scalability.

This application scenario often adopts combination modes such as “Lift + Horizontal Conveyor,” “Lift + RGV,” or “Lift + AGV.” These systems can be configured as left-right loops or vertical loops.

They offer stable and reliable performance, achieving high transport efficiency while significantly minimizing civil engineering requirements and reducing construction costs.

Pallet Circulating Vertical Conveyer

Pallet vertical conveyors are core logistics standard equipment designed for high-intensity, high-efficiency vertical transportation of large goods like pallets between high floors. With exceptional stability, outstanding efficiency, and trustworthy quality, they are the ideal choice for optimizing space utilization and achieving automated logistics.

This model features a conveyor + circulating pallet design, offering the following key advantages:

High Compatibility: Capable of handling various load types, such as pallets, cage carts, AGVs, and all kinds of tooling racks.

Simplified Installation: Equipped with a floor-level interface lift, eliminating the need for excavation or pits.

Enhanced Efficiency: Its double-deck design transports loaded pallets on the upper level and empty pallets on the lower level, significantly improving throughput.

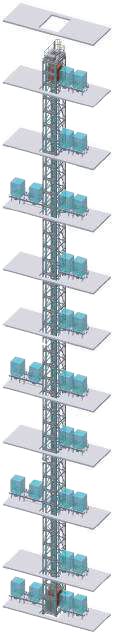

High-Rise Vertical Conveying

The High-Rise Vertical Conveying System is an integrated logistics solution specifically designed for automated, high-efficiency transportation of materials between different elevations, such as different floors, aerial connecting corridors, and elevated warehouses. It consists of vertical lifts and horizontal conveyors seamlessly connected to form a complete closed-loop system.

High-Speed Vertical Conveyer

High speed, low noise, and high positioning accuracy. It boasts a simple, stable structure that is easy to maintain. The lightweight, modular design facilitates installation and transportation. Inlet/outlet configurations are freely combinable (E/F/L type), and the motor can be top or bottom mounted for convenient maintenance. Includes multiple safety protection designs.

Application Scenarios: Airports, Express Logistics, Factory Automation.

Custom Designed Conveying Equipment

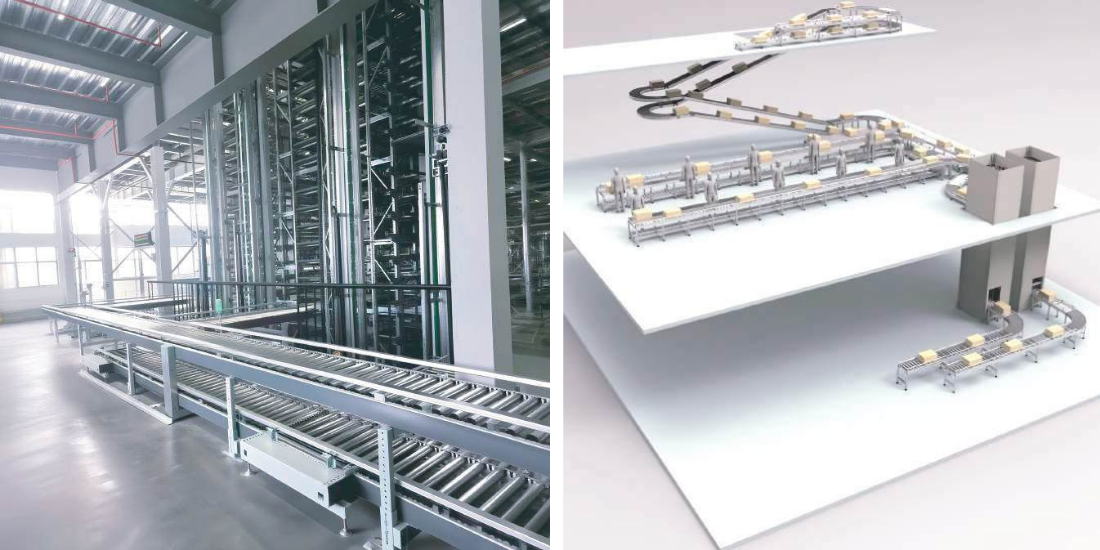

Pallet Horizontal Conveying

The most common application scenario for vertical conveyors. The combination of a vertical conveyor and inbound/outbound connecting conveyors achieves “horizontal + vertical” transportation of pallets. Common loading methods include: pallet jacks, forklifts, automated lines, etc.

Custom Designed Conveying Equipment

Pallet Horizontal Conveying

The most common application scenario for vertical conveyors. The combination of a vertical conveyor and inbound/outbound connecting conveyors achieves “horizontal + vertical” transportation of pallets. Common loading methods include: pallet jacks, forklifts, automated lines, etc.

Light-Duty Continuous Vertical Conveyor Z-Type

The Z-Type vertical conveying system uses a continuous layout, designed for light-duty materials, enabling efficient and energy-saving flow across floors. Its advantages include small space occupation, flexible conveying paths, and seamless integration with automation systems, significantly improving vertical logistics efficiency and space utilization.

Light-Duty Continuous Vertical Conveyor C-Type

The Light-Duty Continuous Vertical Conveyor C-Type system is designed for small and medium-sized items. It adopts a compact continuous vertical layout to achieve efficient and flexible conveying across floors. Its advantages include extremely small space occupation, smooth and low-noise operation, and seamless integration with production lines and sorting equipment, significantly enhancing the level of vertical logistics automation and space utilization.

Heavy-Duty Continuous Vertical Conveyor

The Heavy-Duty Continuous Vertical Conveyor is designed for cross-floor transportation of large-tonnage materials. It offers significant advantages such as high load capacity, high efficiency, high reliability, and space savings. It can seamlessly integrate with automation systems, completely replacing traditional freight elevators.

Rubber Chain Continuous Vertical Conveyor

The Rubber Chain Continuous Vertical Conveyor uses rubber chains as driving components, offering advantages such as quiet, low-noise operation; wear-resistant, easy-to-maintain chain links; no need for lubrication, pollution-free; reasonable structure, high conveying capacity; and long service life. It is widely used in logistics automation systems in airports, new retail, pharmaceuticals, tobacco, and other industries.

BR Reciprocating Vertical Conveying

The BR Reciprocating Vertical Conveyor uses chain drive and frequency conversion control to achieve efficient vertical lifting of goods, saving space and operating smoothly. It is suitable for various production lines and warehousing logistics scenarios.

MR Reciprocating Vertical Conveying

The BR Reciprocating Vertical Conveyor uses chain drive and frequency conversion control to achieve efficient vertical lifting of goods, saving space and operating smoothly. It is suitable for various production lines and warehousing logistics scenarios.

Reciprocating Ultra-High-Speed Tote Vertical Conveying

The Reciprocating Ultra-High-Speed Tote Vertical Conveyor uses an independent lifting mechanism, designed for high-frequency, extremely fast vertical conveying of tote/box materials. Its speed and efficiency far exceed those of traditional lifts, significantly optimizing warehouse logistics tempo.

Box Horizontal Conveyor

The Box-type Conveyor is specifically designed for the continuous vertical conveyance of boxed materials, offering advantages such as high space utilization, stable operation, strong automation connectivity, and high reliability.