Globl's Four-way Shuttle Drives Automotive Warehouse Automation: Seat Giant Case Study

1. Automotive Manufacturing Challenges and Automation Needs

The client, a global leader in the production of automotive seating and headrests, faced severe logistical constraints due to continuous expansion across both passenger and commercial vehicle sectors. To sustain growth, the integration of Automotive Warehouse Automation was critical.

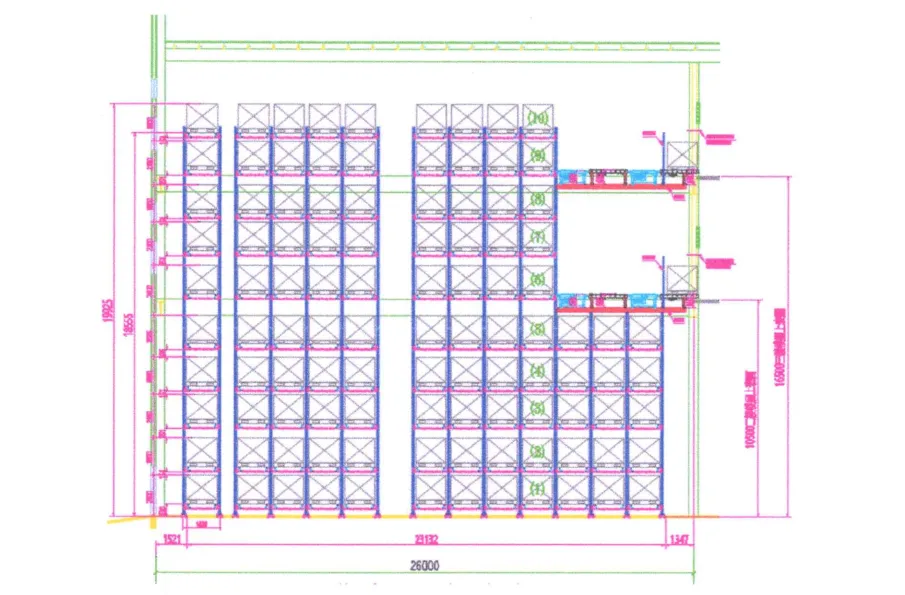

1.1 Globl PTR ASRS Maximizes Auto Parts Storage Density

Inventory Management & Tracking: Complexity and volume demanded accurate, real-time inventory status, a challenge for manual processes.

Space Utilization: Limited warehouse footprint necessitated maximizing High-Density Storage capabilities.

Inefficiency in Manual Operations: Manual handling and storage led to low throughput and high error rates, especially during peak demand.

Product Damage Control: Susceptible finished and semi-finished goods required a precise, automated handling system.

To overcome these, the client partnered with Globl for a specialized Automated Solution.

2. Globl's Four-way Shuttle System for Warehouse Automation

The implemented Globl solution established an Automated Storage and Retrieval System (AS/RS) centered around the Four-way Shuttle technology to deliver High-Density Storage.

2.1 Configuration of the Four-way Shuttle Automation System

The high-density configuration included:

10 Four-way Shuttle Cars: Core devices enabling multi-directional retrieval.

4 Lifting Machines (Vertical Conveyors): Essential for vertical movement.

52 Conveyors (Chain and Roller): Used for horizontal transport and transfers.

The system provided 803 total storage locations, directly realizing High-Density Storage.

3. Workflow of Automotive Warehouse Automation Processes

The system operates via coordinated WMS and WCS commands to automate critical material flows:

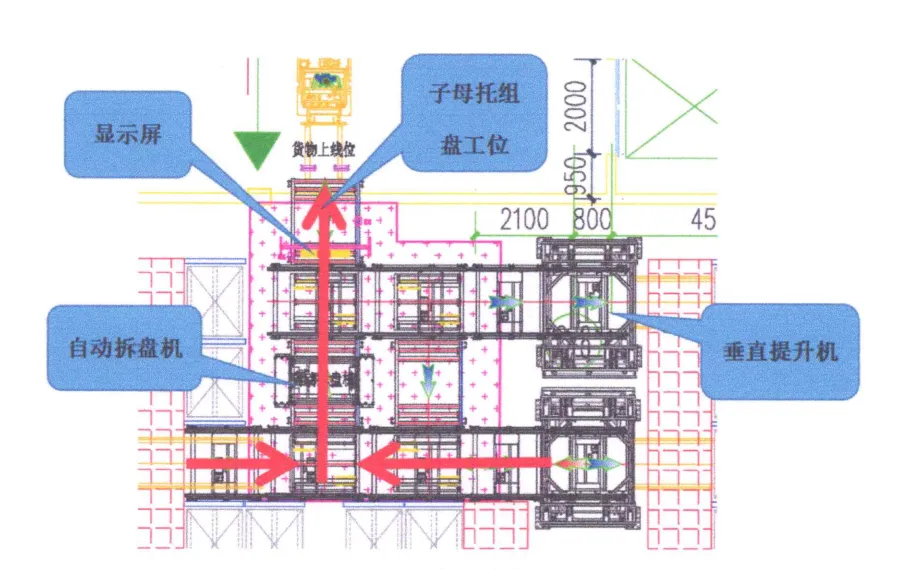

3.1 Automated Goods Inbound Process (Warehouse Automation)

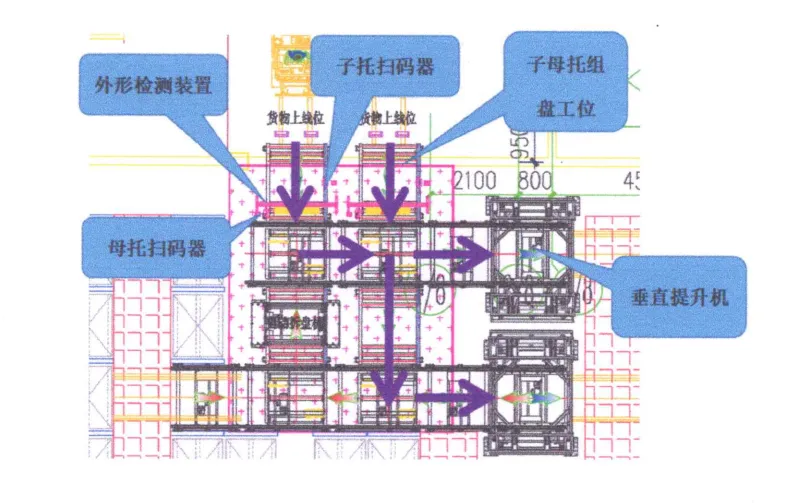

Manual forklifts assemble sub-pallet goods onto a master pallet; the system automatically binds all unit information via scanning.

The WMS issues the inbound task, relaying instructions to the automated equipment.

Goods pass detection, then enter a lift for vertical transport to the designated level.

The Four-way Shuttle takes the goods from the lift exit and places them into the High-Density Storage location.

Inventory data is automatically updated upon completion.

3.2 Automated Goods Outbound and Empty Pallet Return Process (Four-way Shuttle)

WMS issues the outbound task; the Four-way Shuttle retrieves goods and delivers them to the lift.

The lift lowers the goods to the first level.

Goods are conveyed to the docking port for manual forklift pickup.

Remaining empty master pallets are automatically stacked and returned to storage.

System data is updated.

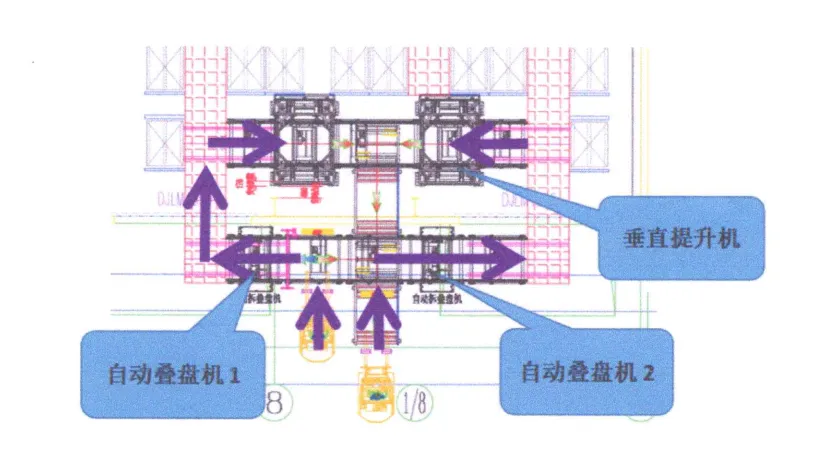

3.3 Automated Empty Pallet Stacking Outbound/Supply Process (Warehouse Automation)

WMS issues the supply task based on production schedules.

The Four-way Shuttle moves the empty pallet stack to the lift, which transports it to an upper floor.

The stack is conveyed to an automatic destacker, separating a single empty master pallet for the assembly station.

The single pallet awaits sub-pallet assembly.

Data is updated.

3.4 Implementation Results of Automotive Warehouse Automation

Efficiency Improvement: Substantial gains in throughput due to continuous, automated operation.

Accuracy Enhancement: Elimination of human error, significantly increasing Inventory Management reliability.

Operational Cost Reduction: Reduced reliance on manual labor, lowering costs and minimizing goods damage.

Storage Space Optimization: Achieved maximum utilization of cubic space via High-Density Storage.

Intelligent Management: Real-time data and optimization tools support smarter supply chain decision-making.

4. Conclusion: Sustaining Growth with Automotive Warehouse Automation

This case study demonstrates the transformative power of Globl‘s expertise in Automotive Warehouse Automation. By deploying the Four-way Shuttle solution, the client successfully overcame critical limitations—from low efficiency to constrained space—establishing a scalable, intelligent foundation for future growth. Investing in this automation technology is proven key to achieving sustainable competitive advantage and securing operational excellence in the complex automotive supply chain.

5. Next Step: Take Action with Globl Four Way Pallet Shuttle

Ready to move your warehouse From Chaos to Efficiency?

The challenges of complexity and low space utilization in automotive logistics require specialized automation expertise.

If your factory is ready to implement smart warehouse solutions and achieve the kind of enhanced efficiency and cost savings detailed in this Globl PTR case study, don’t wait.

Contact the Globl PTR team today to schedule a consultation on how our ASRS and warehouse automation solutions can strengthen your supply chain and prepare you for future growth.